Description

Introduction

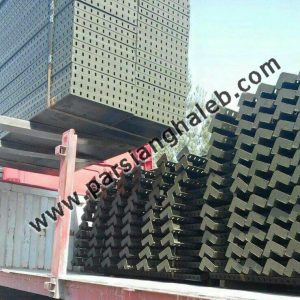

Evolution process of bridge construction shows abundance of effect of technology change on emersion and growth flow of this structure from Roman era up to beginning of 20th century in which use of metal bridges and then Reinforced Concrete Bridge were propounded. Production of tabulating mold is necessary for production of box prefabricated concrete pieces as one of main elements of cable box bridge deck.

Presentation

This mold is designed and manufactured by use of the best modern technology in factories of Parsian Ghaleb Industrial group. The mold works automatically and it is closed and opened by hydraulic system. This system is able to perform pieces related to ramps and arcuate routs.

Structure of mold

Mask: main and fixed part of mold is mask which is manufactured based on lateral segment of bridge deck and cables pass from:

۱- floor chassis, this mold includes two bigger floor chassis with a determined length

۲- there are some holes on it based on dimensions of plan and a small chassis with a determined length

۳- Wall mold includes two left and right wall mold which is closed and opened by hydraulic jacks and fixed by mechanical jacks.

۴- Internal mold is used for internal segment of piece.

۵- A U form cart of internal transportation for maintaining and regulating internal mold. Concrete system uses from the mentioned cart including three floors and able to have lateral, vertical, and rotational movement.

۶- Hydraulic of all parts of tabulating mold is closed and opened by hydraulic jacks.

۷- electricity network

۸- vibration system

Application

In fact, operation of unleveled cross roads is more considered by Tehran civil plans officials by relying on production of concrete pieces of bridge pile and deck and projects such as stone caravansary 2, Sheikh Fazlollah-Jenah expressway crossroad, ramp bridges, Sadr exp. project are the plans under operation by box bridge methods. This technique namely operation of bridge by box concrete refabricated pieces is the most suitable and rapid and economic method of bridge construction at unleveled crossroads.

Advantages

if definition of prefabricated is that manufacture of structural elements in mass in factory and then installation, then there will be some advantages for it which are as follows: to shorten schedule of project due to manufacturing at factory, being high grade f pieces due to accuracy in production, being inexpensive, to observe regulation of energy lost and limit of error domain. Clear advantages of bridge tabulating pieces are that they are produced in factory, and consequently, climate conditions have not role in concreting process and the pieces are produced at standard temperature conditions and then transferred to place of project. Studies show that use of box bridges has not a long record in the world. History of this transportation structure is just reach to half century but during these years, box bridges are incomparable bridges due to controllable conditions of production and lack of error in their operation.

We have also stepped in bridge construction aiming to make traffic flow and remove problems of transportation along with urban spaces development for easy access to heavy and light vehicles in urban unleveled cross roads using box concrete bridge technology and pre-stressed technology and pile and deck manufacturing.

Elements and operation of tabulating mold (Deck)

۱- Mask

Main and fixed segment of mold is mask which is manufactured based on lateral segment of bridge deck and cables pass from holes on it. Shear keys are installed on mask by bolt and nut. Considering to type of mold design, centimeter is variable. For changing a-+, length of piece may be in thickness of piece and mask is equipped with filers with various dimensions which are installed inside mask.

۲- floor chassis

Tis mold includes two greater floor chassis with a determined length and are based on dimensions of plan and one small chassis which is put on mask and connected to ground by mechanical jacks. One of great chassis is connected to small chassis and used as floor of mold. Another great chassis is used for keeping piece and putting it in a suitable position. Any great chassis has 4 mechanical bolts and it is possible to produce ramp pieces by change of bolts size. Any great chassis is equipped with filler piece which is used for overlapping previous piece.

۳- wall mold

It includes two left and right wall mold which is closed and opened by hydraulic jacks and fixed by mechanical jacks. After regulating molds, there is no need to replacing mechanical jacks and the walls will be closed and opened by hydraulic jacks and fixed by pins of mold supporting system for concreting position.

۴- Internal mold

It is used for internal segment of piece which is installed on transportation cart of internal mold and regulated by four hydraulic jacks. As internal thickness of bridge deck is variable, internal mold is made in sliding form and regulated by mechanical bolts. At first, internal mold shall be separated and transferred to back of mask which is performed by hydraulic jacks installed on mold wall and hydro-motor of cart.

۵- cart of internal transportation

It is a U form cart equipped with hydro-motor system and used for maintaining and regulating internal mold. Mechanical jacks of cart are necessary to be connected and used as base during concreting. Transportation cart of internal mold has 4 jacks for regulating height of mold and 4 jacks for collecting mold and its separation from concrete piece. Two hydro-motor devices are installed on back wheels of cart to move it.

۶- Transportation cart

It is used for transporting floor chassis and concrete piece which includes 3 floors and able to have lateral, vertical, and rotational movement.

۷- Hydraulic system

All parts of tabulating mold are closed and opened by hydraulic jacks. For this purpose, four 10 tones jacks are installed on wall molds. Use of hydraulic systems of tabulating mold depends on observing security principles of application until all involving elements do their works in best form in a manner that pressure of hydraulic system shall not be more than 130 times until not damage jacks and hydro-motors.

۸- electricity network

۹- vibration system

It includes vibration system which transfers necessary wind of vibrators by UPVC valves of this system. It is mentionable that internal pieces of pneumatic vibrations shall be saturated by gas oil until not suffer from corrosion due to steams. any mentioned elements includes a set pieces and tools which have a unique production process and are result of designing and manufacturing. All segments of tabulating mold are closed and opened by hydraulic jacks.

Mold assembly

Before commencing assembly, it is necessary to provide some arrangements and make environment conditions ready. Therefore, flooring and foundation shall be ready based on executed plans and necessary rails are installed on floor. Time of assembling each mold is 7 days which depends on suitable conditions of workshop.

Reviews

There are no reviews yet.